Vertical Shaft Impactor VSI Crusher

VERTICAL SHAFT IMPACTOR

Vertical Shaft Impactor, VSI CRUSHER, Vertical Shaft Impactor Plant or Vertical Shaft Impactor Crusher (VSI Crusher) is manufacturing supplying & exporting by Shree Conmix Engineers Pvt. Ltd. in Ahmedabad, Gujarat, India. Which is known as “Sand Making Machine” as well as “Rubble Shaping Machine“. Vertical Shaft Impactor (VSI Crusher), Vertical Shaft Impactor Plant is used in the quarrying industries for the production of high quality aggregates & also used for production cubical sand from aggregates.

The material enters through the feed tube into a closed rotor assembly. Then it is thrown against an angular rock bed by high speed impeller, which gives high velocity & Swirling action to the material. It is widely used in all kinds of hard and brittle materials for medium, fine crushing. Such as, rocks, abrasive, refractory, cement clinker, quartz, iron ore and concrete aggregate and so on, and building sand, building road gravel are the most appropriate.

In this Shaft Impactor that combination of variables of rotor speed & feed height better control of finer product can be achieved.

Shree Conmix Engineers Pvt Ltd. is introduce India’s best wide range of Vertical Shaft Impactor Or VSI Crusher. Our Impact Crushers are designed to exceed the primary needs of customers in the mining, aggregates and recycling industries.

VERTICAL SHAFT IMPACTOR SERVICES

Vertical Shaft Impactor (VSI CRUSHER) is unique due to its crushing process. Whereas most other types of crusher use metallic parts to crush rock, and the rock fed into the machine to crush itself.

This autogenous crushing process produces the best-shaped aggregate on the market today.

Vertical Shaft Crushing machines designed to operate as third or fourth stage crushers in the processing of all types of rock, ores and minerals.

Working principle of conmixcrusher’s vertical shaft impactor is totally different than horizontal shaft impactor. It has a high speed rotor with wearing resistant tips and main chamber (crushing chamber) is designed in such a way so that speed rotor throw the rocks against the high crushing chamber. In vertical shaft impactor crusher predominant force is the velocity of speed rotor.

Shree Conmix Engineers Pvt. Ltd. is a famous for Vertical Shaft Impactor Crusher in India which was established in 1990. Our VSI Crusher have been sold overseas with its high quality and effectiveness. You are welcomed to contact us via email or phone and we are waiting for your visit at any time.

APPLICATIONÂ

- Road Base

- Gravel And Glass

- Sand and Cement

- Corundum

- Ferro silicon, Refractories

- Silicon Carbide

- Tungsten Carbide and Zeolite

- Bauxite And Iron ore

- Burnt Magnesite

ADVANTAGESÂ

- Quick and easy installation. Crushers require minimum support structure

- It ideal as mobile units

- More tolerant than conventional crushers to difficult feed conditions.

- Range of models available to suit any capacity in tertiary or quaternary applications.

- Very cubicle product

- Beneficial of material (elimination of soft stone).

- Gradation consistency.

- High product yield.

- Simple maintenance.

- High throughput capacity

- Low capital investment

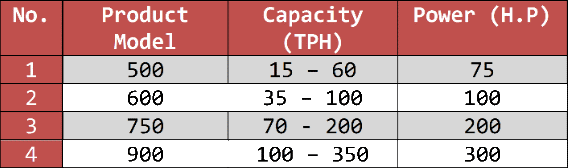

TECHNICAL SPECIFICATION

Jaw Crusher Working Principle

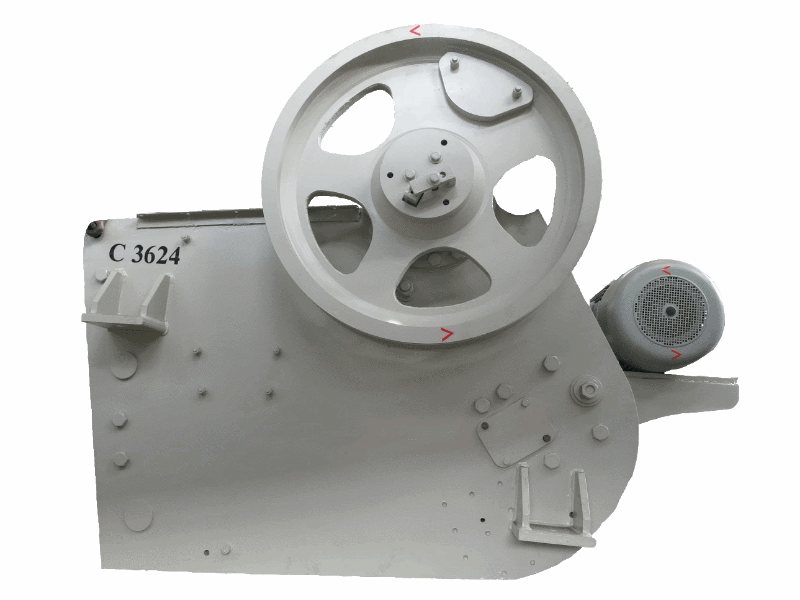

JAW CRUSHERS

Jaw Crusher , Primary Jaw Crusher, Single Toggle Jaw Crusher, Portable Jaw Crushers are manufacturing , supplying and exporting by  Shree Conmix Engineers Pvt Ltd. in Ahmedabad, Gujarat, India.

Sheree Conmix Enigneers Pvt. Ltd. is introducing a huge range of Jaw Crushers, Cone Crusher, VSI Crushing And Screening Machine. Sheree Conmix Enigneers Pvt. Ltd. is not name, it is huge brand in Ahmedabad, Indiana Market.

Conmix Jaw Crushers are the most advanced and reliable in the market and are highly productive in a variety of applications.

Conmix Jaw Crusher is based on a revolutionary modular, non-welded frame construction, offering owners the highest possible fatigue strength, excellent reliability and numerous mounting possibilities.

It is also providing  Single & Double Toggle Grease Jaw Crushers, Coal Crushers with special high-quality cast steel components and durable wear parts, means exceptionally high crusher availability, cost-efficient crushing and low cost per ton.

JAW CRUSHERÂ WORKING PRINCIPLE

Jaw Crushers are classified on the basis of the position of the pivoting of the swing jaw

- Blake crusher-the swing jaw is fixed at the upper position

- Dodge crusher-the swing jaw is fixed at the lower position

- Universal crusher-the swing jaw is fixed at an intermediate position

Conmix Jaw crushers are equipped with one fixed and one movable crushing jaw , both of which support crushing plates (wearing parts) in several versions. They form a wedge-shaped crushing part. The walls of the crushing zone are made of replaceable wearing sheets. Crushing is done between the two crushing jaws. The moving jaw of the single toggle jaw crusher moves elliptically. A pendulum motion is being carried out by the double toggle jaw crusher.

The crushing force is produced by an eccentric shaft. Then it is transferred to the crushing zone via a toggle plate system and supported by the back wall of the housing of the machine. Spring pulling rods keep the whole system in a condition of non positive connection. Centrifugal masses on the eccentric shaft serve as compensation for heavy loads. A flywheel is provided in the form of a pulley.

Shree Conmix Engineers Pvt. Ltd. is a famous for Jaw Crusher and Cone Crusher in India which was established in 1990. Our jaw crusher have been sold overseas with its high quality and effectiveness. You are welcomed to contact us via email or phone and we are waiting for your visit at any time.

CONSTRUCTION OF CONMIX JAW CRUSHER

Conmix Single Toggle Jaw Crushers are uses only one toggle plate in its mechanism. Single toggle jaw crushers are provided in heavy and light versions with welded steel housing and a moving jaw in a welded or cast steel version, as well as an eccentric shaft made of high-grade forged steel.

Conmix jaw crushers with a double toggle system are either built with heavy or light welded steel housings, with a moving jaw and a pulling rod in either welded or cast steel versions, as well as an axis and an eccentric shaft made out of high-grade forged steel.

APPLICATIONÂ

- Mining

- Aggregate

- Demolition

- Construction

- Environmental

- Granite, River gravel

- Lime Stone, Coal

ADVANTAGESÂ

- high and constant capacity.

- Single toggle Grease lubricated Crusher

- high operational reliability

- long service and lifetime.

- Interchangeable and reversible jaw plates.

- broad range of application.

- easy replacement of wear and spare parts

- ow maintenance requirements.

- High throughput, high degree of size reduction

- Easy-to-clean crushing chamber.

TECHNICAL SPECIFICATION

Cone Crusher

CONE CRUSHER

Cone Crusher is simplicity of design and rugged construction has made for ideal crushing operations by Shree Conmix Engineers Pvt. Ltd. For the most efficient and economical production, a wider range of Conmix Cone Crusher models are available for you yo choose from. The Cone Crusher has remarkable high nominal effective stroke and cavity range, which really brings great benefits and flexibility to the process. The large feed opening allows the possibility for the Conmix Cone Crusher to be used as a secondary crusher as well.

Conmix Cone Crusher range of mobile cone crushers are suitable for secondary and tertiary crushing in direct feed applications. The range uses advanced Track Mounted Cone Crusher is to provide high volumes of excellently shaped product In Ahmedabad, India.

CONE CRUSHER WORKING PRINCIPLE

The working principle of Conmix Cone Crusher® is to be useful for primary crushing, secondary crushing and final crushing as well.

With the higher production and higher quality, it is becoming more and more popular among construction companies. What’s more, its lower cost and easier maintenance promote its popularity.

This Crusher is play an important role in different industries, such as construction industry, chemical industry and metallurgical industry. It can be used to crush both hard and medium hard materials, such as limestone, iron ores and copper ores. When it comes to its production cavity, it is based on the types of the materials.

The main parts of this Crusher is transmission device, crushing cone, bowl-shaped bearing, frame and hollow eccentric shaft. Besides, the size of the crushed materials is adjustable. You can adjust the discharge opening by the springs and hydraulic pressure station to produce materials which are suitable for your project.

When the Crusher is operated, the powerful motor drives the shaft. Then the shaft will force the axle of crushing cone wings to swing and the crushing wall will move against each other.

Finally, the materials will be pressed and crushed. The materials which are in suitable size will drop through the discharge opening. Compared with other crushers, the working principle of cone crusher is more powerful.

Shree Conmix Engineers Pvt. Ltd. is a famous for Cone Crusher® manufacturers in India which was established in 1990. Our Cone Crusher® have been sold overseas with its high quality and effectiveness. You are welcomed to contact us via email or phone and we are waiting for your visit at any time.

APPLICATION

- Mining

- Aggregate

- Demolition

- Construction

- Environmental

- Granite, River gravel

- Reduced no-load head spin

- Increased reliability

- Reduced maintenance

- Â More efficient use of electrical power

ADVANTAGES

- First Indigenous manufacturer of track mounted mobile crushing plant with cone crusher.

- Quick replacement of wear parts.

- Specially designed crushing chamber gives constant high production & uniform gradation throughout the wearing life.

- Hydraulic gap adjustment. And Bearing system permits higher R.P.M.

- Higher fulcrum point and increased throw perform more work per cycle.

- New tramp release system provides better protection from mechanical overload.

- New hydraulic adjust system allows faster bowl removal and less maintenance.

- New head nut installs easier and faster

- Reduced no-load head spin.

- Productivity and consistency.

- More efficient use of electrical power.

- Increased reliability and reduced maintenance.

TECHNICAL SPECIFICATION

Jaw Crusher

Jaw Crushers®, Jaw Crusher Plant, Jaw Crusher Machines, Jaw Crusher India are designed to exceed the primary needs of customers in the mining, aggregates, concrete construction, crushing and screening and recycling industries. And it is also providing India’s best and highest selling wide range of Single Toggle Jaw Crusher, Primary Jaw Crusher with special high-quality cast steel components and durable wear parts, means exceptionally high crusher availability, cost-efficient crushing and low cost per ton which is manufacturing, exporting and supplying by Shree Conmix Engineers Pvt. Ltd.® in Ahmedabad, India.

Shree Conmix Engineers Pvt. Ltd.® is a famous for Jaw Crusher, Cone Crusher, Vsi Crusher, Micro Cone Crusher Plant, Track Mounted Crushing and Screening Plant, Semi Mobile Crushing and Screening Plant, Stationary Crushing and Screening Plant, Vibrating Screens and Feeders, Concrete Batching and Mixing Plant, And Transit Mixer in Ahmedabad, India. Which was established in 1990. Our All Type of Crushing & Screening and Batching & Mixing Products have been sold overseas with its high quality and effectiveness.

Jaw Crushers are designed to exceed the primary needs of customers in the mining, aggregates and recycling industries by Shree Conmix Engineers Pvt. Ltd. And it is also providing India’s best and highest selling wide range of Single Toggle Jaw Crushers, Jaw Coal Jaw Crushers, Primary Jaw Crushers with special high-quality cast steel components and durable wear parts, means exceptionally high crusher availability, cost-efficient crushing and low cost per ton in Ahmedabad, India.

Jaw Crusher is consists of many parts, like eccentric draft, frame, large belt wheel mobile jaw crusher, flying wheel, toggle jaw plates, gap adjustment screw and so on. The main function of Jaw Crusher is to crush large rocks into smaller rocks, gravel, rock dust and gravel to satisfy different requirement for the products. Conmix Jaw Crusher® is engineered for the toughest best feed materials.

Structure of Conmix Jaw Crusher® is mainly include frame, eccentric shaft, big pulley, flywheel, moving jaw, side guard plate, toggle plate, toggle plate back seat, adjusting screw gap, the reset spring, fixed jaw plate and movable jaw etc. The Toggle Jaw Plate is also play a role as insurance bracket. Working part of jaw crusher is two pieces of jaw plate, one is fixed jaw plate (fixed jaw), vertical (or slightly upper chamber) fixed in the front wall of the body, and the other is movable jaw plate (moving jaw), location inclined to form the next big small crushing chamber (working chamber) and the fixed jaw.

Jaw Crusher is based on a revolutionary modular, non-welded frame construction, offering owners the highest possible fatigue strength, excellent reliability and numerous mounting possibilities.

JAW CRUSHER WORKING PRINCIPLE

Jaw Crusher is widely used in industrial and mining enterprises , this is because the aircraft structure is relatively simple , and has a large range of models. Jaw Crusher is mainly used as the primary crusher. It can be used with mineral processing equipment, gravel ancillary equipment, it also can be used alone.

Structure of Jaw Crusher is mainly include frame, eccentric shaft, big pulley, flywheel, moving jaw, side guard plate, toggle plate, toggle plate back seat, adjusting screw gap, the reset spring, fixed jaw plate and movable jaw etc. The Toggle Jaw Plate is also play a role as insurance bracket. Working part of jaw crusher is two pieces of jaw plate, one is fixed jaw plate (fixed jaw), vertical (or slightly upper chamber) fixed in the front wall of the body, and the other is movable jaw plate (moving jaw), location inclined to form the next big small crushing chamber (working chamber) and the fixed jaw.

Jaw Crusher for crushing materials work, is the material between the two pieces of jaw plate crushing. Motor drive transmission mechanism driven jaw plate hanging around the shaft relative to the fixed jaw do periodic reciprocating motion, sometimes close, sometimes leaving in the process of moving jaw plate close to the fixed jaw plate, is the material between the two jaw plates pressed on the subject broken, bent and broken fracturing, the process was moving away from the fixed jaw plate, the material has been crushed under the action of gravity, through the discharge port of discharge.

SINGLE TOGGLE JAW CRUSHER

Single Toggle Jaw Crushers® are uses only one toggle plate in its mechanism. Two bearings are fit in the swing jaw of this Crusher and the other two bearings support the eccentric shaft, which is driven by the drive flywheel. An extra (non-drive) flywheel is provided to lessen the power requirement of the prime mover (motor or engine).

Being light in size and relatively easy to operate and maintain, the Conmix Crushers are a popular machine for use in hilly terrain and for mobile crushing plants.

Single Toggle Jaw Crusher® is generally used where size distribution is not of paramount importance but productivity is to be maximized with lower power consumption. These do not require high operating skill and gap setting is simpler. Also, the maintenance requirement is much lower.

Single Toggle Jaw Crushers® feature are large gape feed openings, high production and low operating costs. These rugged machines are manufactured with heavy duty parts for constant operation and long life. Typical applications for our single-toggle jaw crushers are in mining, quarrying and recycling. The Jaw Crushers handle ores, rock, gravel and recycled concrete.

WHY CHOOSE OUR JAW CRUSHER

Conmix Jaw Crusher® is crushed under high pressure between one fixed and one movable crushing jaw. The grinding parts are available in various steel types, hard metal tungsten carbide and zirconium oxide to prevent undesired abrasion. And the motor inside the jaw crusher will drive the belt and belt pulley, forces the mobile jaw to move up and down through eccentric shaft. While the mobile jaw is lifting, the angle between lining plate and moving jaw becomes large, and this will push moving jaw plate close to the fixed jaw plate.

During the process of operation, the material is crushed and ground and the crushing will be done. While when the jaw is going down, the angle will certainly become smaller, the moving jaw plate will leave the fixed jaw plate on account of the effect of pulling bar and spring, and then the crushed material will be discharged from the lower opening of the crushing room.

While when the jaw is going down, the angle will certainly become smaller, the moving jaw plate will leave the fixed jaw plate on account of the effect of pulling bar and spring, and then the crushed material will be discharged from the lower opening of the crushing room. While the motor is rotating continuously, the mobile jaw will carry out periodical press and discharging and implement mass production.

For primary crushing of medium-hard to very hard material Conmixcrusher is offering a wide range of efficient and proven Single Toggle Jaw Crusher®, Primary Jaw Crusher®, Portable Jaw Crusher®, Track Mounted Jaw Crusher®.

APPLICATIONÂ

- Mining

- Aggregate

- Demolition

- Construction

- Environmental

- Granite, River gravel

- Lime Stone, Coal

ADVANTAGESÂ

- Modular Design increasing fatigue strength.

- Single toggle Grease lubricated Crusher

- Remarkable reduction ratio

- Fly wheel design that delivers perfect inertia and least vibration.

- Interchangeable and reversible jaw plates.

- Sprinkler System (Optional) & Grease Pump (Optional)

- The bearing parts labyrinth sealing process using multi-layer, extending bearing life.

- High throughput, high degree of size reduction

- Easy-to-clean crushing chamber

- Low operating cost.

- Hydraulic CSS adjustment.

- Energy-saving equipment: stand-alone energy-saving 15% to 30%, saving more than double.

- Stable and reliable, with overload protection device.

- Absence of stress inducers such as weld seams assures excellent durability against shock loads.

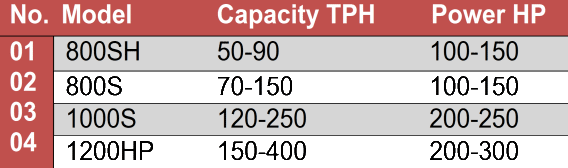

TECHNICAL SPECIFICATION

Jaw Crusher Manufacturers In India

JAW CRUSHERÂ MANUFACTURERS IN INDIA

“JAW CRUSHER” BY SHREE CONMIX ENGINEERS PVT. LTD.

“Shree Conmix Engineers Pvt Ltd.“  is leading manufacturer, supplier and exporter of the Jaw Crusher from Ahmedabad, Gujarat, India.

Shree Conmix Jaw Crusher Manufacturers In India is based on a revolutionary modular, non-welded frame construction, offering owners the highest possible fatigue strength, excellent reliability and numerous mounting possibilities.

The accurately balanced structure, the jaws are easy and economical to install. Combined with special high-quality cast steel components and durable wear parts, means exceptionally high crusher availability, cost-efficient crushing and low cost per ton.

Jaw Plates and other wear parts are designed for high performance and with low operating costs. The life of the wear parts are extended due to the selection of high quality material, proven design and all Jaw Plates are interchangeable and reversible.

Jaw Crusher Manufacturers In India is premium class crushers due to their design as well as to the materials that are used to produce them. Attention has been paid to even the smallest details, so as to ensure the highest possible functionality and reliability, without any compromises. Those who have owned and operated our jaw crushers know that not all jaw crushers are the same!

Shree Conmix Engineers Pvt. Ltd. provide a comprehensive array of highest caliber Jaw Crusher, Mobile Crusher Plant, Impact Crushers, Roll Crushers, Vibrating Screens, Vibrating Feeders using the latest technology in India. We recommend the most appropriate machines and equipments to our need efficiently and economically.

Our well experience, dedicated team with well-equipped workshop made “Shree Conmix Engineers Pvt. Ltd. Jaw Crusher” a brand name in the market in the field of Crushing Equipment. Shree Conmix Engineers Pvt. Ltd. is committed to quality of the products. The quality products manufactured by Shree Conmix Engineers Pvt. Ltd. is “Jaw Crusher“,  “Cone Crusher“,  “Vertical Shaft Impactor“,  “VSI Crusher“,  “Micro Cone Plant“,  “Sand Making Machine“,  “Rubble Shaping Machine“,  “Vibrating Screens and Feeders“,  “Concrete Batching and Mixing Plant“,  “Track Mounted Mobile Crushing and Screening Plants“,  “Semi Mobile Crushing and Screening Plants“,  “Stationary Crushing and Screening Plants“,  “Transit Mixers“

Shree Conmix Engineers Pvt. Ltd. is a famous “Jaw Crusher Manufacturers In India“Â which was established in 1990. Our jaw crusher have been sold overseas with its high quality and effectiveness. You are welcomed to contact us via email or phone and we are waiting for your visit at any time.

“Jaw Crusher Manufacturers In India“

APPLICATIONÂ

- Mining

- Aggregate

- Demolition

- Construction

- Environmental

- Granite, River gravel

- Lime Stone, Coal

ADVANTAGESÂ

- Modular Design increasing fatigue strength.

- Single toggle Grease lubricated Crusher

- Remarkable reduction ratio

- Fly wheel design that delivers perfect inertia and least vibration.

- Interchangeable and reversible jaw plates.

- Low operating cost.

- Hydraulic CSS adjustment.

- High throughput, high degree of size reduction

- Easy-to-clean crushing chamber

- Sprinkler System (Optional) & Grease Pump (Optional)

- Absence of stress inducers such as weld seams assures excellent durability against shock loads.

TECHNICAL SPECIFICATION

Cone Crusher Manufacturers

CONE CRUSHER MANUFACTURER IN INDIA ?

CONE CRUSHER WORKING PRINCIPLE

Shree Conmix Engineers Pvt. Ltd. is a famous for Cone Crusher manufacturers in India which was established in 1990. Our cone crusher have been sold overseas with its high quality and effectiveness. You are welcomed to contact us via email or phone and we are waiting for your visit at any time.

Cone Crusher is simplicity of design and rugged construction has made for ideal crushing operations. For the most efficient and economical production, a wider range of Conmix Cone Crusher models are available for you to choose from. Cone Crusher has remarkable high nominal power, effective stroke and cavity range, which really brings great benefits and flexibility to the process. The large feed opening allows the possibility for the Cone Crusher to be used as a secondary crusher as well.

Conmix Cone Crusher range of mobile cone crushers are suitable for secondary and tertiary crushing in direct feed applications. The range uses advanced Cone Crusher® Technology to provide high volumes of excellently shaped product.

Cone Crusher Manufacturers In India is that to be useful for primary crushing, secondary crushing and final crushing as well.

With the higher production and higher quality, it is becoming more and more popular among construction companies. What’s more, its lower cost and easier maintenance promote its popularity.

The cone crusher plays an important role in different industries, such as construction industry, chemical industry and metallurgical industry. It can be used to crush both hard and medium hard materials, such as limestone, iron ores and copper ores. When it comes to its production cavity, it is based on the types of the materials.

The main parts of the cone crusher are transmission device, crushing cone, bowl-shaped bearing, frame and hollow eccentric shaft. Besides, the size of the crushed materials is adjustable. You can adjust the discharge opening by the springs and hydraulic pressure station to produce materials which are suitable for your project.

When the cone crusher is operated, the powerful motor drives the shaft. Then the shaft will force the axle of crushing cone wings to swing and the crushing wall will move against each other.

Finally, the materials will be pressed and crushed. The materials which are in suitable size will drop through the discharge opening. Compared with other crushers, the working principle of cone crusher is more powerful.

APPLICATIONÂ

1. Mining

2. Aggregate

3. Demolition

4. Industrial

5. Construction

6. environmental

7. Granite, river gravel

8. Reduced no-load head spin

9. Increased reliability and reduced maintenance

10. More efficient use of electrical power

FEATURESÂ

1. First indigenous manufacturer of track mounted mobile crushing plant with cone crusher

2. Quick replacement of wear parts

3. Uniform gradation throughout the wearing life

4. Specially designed crushing chamber gives constant high production

5. Hydraulic gap adjustment

6. Bearing system permits higher r.p.m.

7. Higher fulcrum point and increased throw perform more work per cycle

8. New tramp release system provides better protection from mechanical overload

9. New hydraulic adjust system allows faster bowl removal and less maintenance

10. New head nut installs easier and faster

11. Productivity and consistency

Why Choose Our Jaw Crusher

Why Choose Our Jaw Crusher From Others ?Â

Why choose jaw crusher ? Our Conmix Jaw Crushers are premium class crushers due to their design as well as to the materials that are used to produce them. Attention has been paid to even the smallest details, so as to ensure the highest possible functionality and reliability, without any compromises. Those who have owned and operated our jaw crushers know that not all jaw crushers are the same!

Shree Conmix Engineers Pvt. Ltd. is a famous jaw crusher manufacturers in India which was established in 1990. Our jaw crusher have been sold overseas with its high quality and effectiveness. You are welcomed to contact us via email or phone and we are waiting for your visit at any time.

https://www.conmixcrusher.com/jaw-crusher/

COMPETITOR ANALYSIS

CONMIX CRUSHER

Features Application Modular Design increasing fatigue strength Mining Single toggle Grease lubricated Crusher Aggregate Remarkable reduction ratio Demolition Fly wheel design that delivers perfect inertia Industrial Interchangeable and reversible jaw plates Construction Low operating cost Environmental Hydraulic CSS adjustment Granite, River gravel Sprinkler System (Optional) Limestone. Coal Grease Pump (Optional) High throughput high degree of size reduction high degree of size reduction Easy-to-clean crushing chamber

COMPETITOR I

Features Application Heavy Duty Jaw Crusher Design Mining Long Life Aggregate Cost Effective Demolition Standard Replacement Parts Industrial High Productivity Construction Environmental

COMPETITOR 2

Features Application High throughput, high degree of size reduction Mineralogy High final fineness (down to d90 <0.5 mm) metallurgy Zero point adjustment for wear compensation ceramics and glass Breaking jaws made of different materials materials research No-rebound feed hopper Construction materials Easy-to-clean crushing chamber Environmental Analysis Belleville spring washer provides overload protection

Excon-2013

Excon-2013

Confederation of Indian Industry (CII), Indiaâs premier industry association will be organizing Excon-2013. And Our Company Shree Conmix Engineers Pvt Ltd. was successfully participated in Excon-2013.

The 7th International Construction Equipment and Construction Technology Trade Fair, between 20 â 24 November 2013 at Bangalore International Exhibition Centre, Bengaluru, India.

Presently in its 7th Edition, the International Construction Equipment and Technology Trade Fair is supported by the Indian Construction Equipment Manufacturers Association (ICEMA) as Sector Partner for the event.

Excon-2013, the premiere exhibition of Construction Equipment (CE), played a key role in positioning India as a global hub for construction equipment manufacturing.

Drawing 800 exhibitors from 20 countries, this edition witnessed the largest Industry and visitor participation since its launch in 1995, making Excon-2013 the biggest-ever exhibition.

There were country pavilions from China, Finland, Germany, Italy, South Korea, Sweden, Turkey and  the UK, reiterating the potential of the Indian construction industry to grow to $5 marker share of $ ? 2.9 billion.

EVENT FACTSHEET

- Largest Construction Equipment Exhibition in South Asia

- 2,00,000 Square meters of exhibition display area

- UFI Approved Event

- 731 Exhibitors

- 28,332 Business Visitors

- 243 Products Launched

- 9 Country Pavilions China, Finland, Germany, Hongkong, Italy, South Korea, Sweden, Taiwan, Turkey, UK & USA

- Rs 600 crores Business enquiries generated at Excon 2013

- 20 Countries Participated

- 7 Country Pavilions

- 5 Days of International Exhibition

StoneMart 2013

StoneMart 2013

Shree Conmix Engineers Pvt Ltd. was successfully participated in StoneMart 2013. The India StoneMart 2013 was the 7th International Stone Industry Exhibition held between 31 January 2013 – 3 February 2013 and successfully concluded at Export Promotion Industrial Park, Jaipur, Rajasthan, India.

With abundant and practical activities, India StoneMart 2013 provided exhibitors an excellent platform to realize industry communication, brands promotion, market development, supply and demand, and provided opportunity for joint ventures as well as networking.

India StoneMart 2013 was the largest exposition on stone industry which showcased the world of natural dimensional stones, ancillary products and services, comprehensively, conveniently and competently.

It was an all encompassing expositional umbrella which brought together the who’s and who’s of stone industry not only from India but also globally.

The exhibition was organized by CDOS with FICCI as co-organiser, supported by the Government and sponsored by the biggest names in the sector from India and other countries as well.

Rajasthan State Industrial Development Investment Corporation Ltd., was the Principal Sponsor.

The Exhibitors Profile at Stonemart this year covers:

- Stone Quarry Owners & Stone Processors

- Value Added Stone Craft Units

- Exporters & Importers of Natural Stone Products

- Material Handling & Earthmoving Machineries Manufacturers

- Abrasives & Industrial Chemicals

- Transporters & other Service Providers for Stone Industry

- Testing & Standardization Organizations

- Technical Experts & Consultancy Organizations

- Manufacturers, Traders & Exporters of Stone related Machineries & Equipments, Tools & Consumables

- Trading & Marketing Organizations

- Chambers of Commerce

- Associations related to Stone Industry

- Technical Press & Media

IMMI-2014

IMMI-2014

Shree Conmix Engineers Pvt Ltd. was successfully participated in IMMI-2014.  The IMMI-2014 Indian mining sector plays a pivotal role in the country’s infrastructure and economy. Globally, India ranks 2nd in Chromite, 3rd in Coal & Lignite and Bauxite, 4th in Iron ore and 5th in Manganese.

The future of the mining sector lies in laying emphasis on scientific mining so that state of the art technology is used for exploration, efficiencies are realized, clean technologies and safe mining practices are adopted with adequate supporting infrastructure.

India was estimated to have spent $14 billion on coal imports last fiscal year and that figure is likely to rise to $25 billion by 2013/14.

This combined with factors like the widening Current Account Deficit, depreciation of the Indian currency , and need for enhancing infrastructure for bringing back growth in the economy has made sure that the Government has introduced a slew of measures to facilitate / enhance mining in India.

FUTURE OF THE MINING INDUSTRY

- Despite the slowdown, India is still the second-fastest growing economy, after China.

- Demand for minerals, as well as for mining services, is robust in the country.

- Mining in India is becoming more structured, and companies have started outsourcing part of the project to mining service companies.

- The largest mining company in India, i.e., Coal India Limited (CIL), plans to invest around INR254 billion during the Twelfth FYP (2012-17).

- Contract mining could prove to be a solution to the on-going current coal deficit in country.

- As the industry focuses on adapting international levels of technology, there exists untapped potential in the Indian mining equipment sector.

IMMI-2014 Â TO FEATURE

- 4 Day International Exhibition

- 2 Day Global Mining Summit

- 400+ Exhibitors from India and abroad

- 10000+ Business visitors

- 100,000 Square Meters of Exhibition Display area

- B2B networking forum for Visitors / Exhibitors

- Country Pavilion from Australia, Canada, China, Germany, Indonesia, Italy, Poland, Russia, and UK

- Participation from Major Indian companies, Government, PSU’s, Nodal Agencies, Media and others.

Excon-2015

Excon-2015

Confederation of Indian Industry (CII), Indiaâs premier industry association will be organizing Excon-2015. Shree Conmix Engineers Pvt Ltd. was participated in Excon-2015.

The 8th International Construction Equipment and Construction Technology Trade Fair, between 25th – 29th November 2015 at Bangalore International Exhibition Center, Bengaluru, India.

Presently in its 8th Edition, the International Construction Equipment and Technology Trade Fair is supported by the Indian Construction Equipment Manufacturers Association (ICEMA) as Sector Partner for the event.

Excon 2015, the premiere exhibition of Construction Equipment (CE), was held from 25-29 November in Bangalore, played a key role in positioning India as a global hub for construction equipment manufacturing.

Drawing 809 exhibitors from 22 countries, this edition witnessed the largest Industry and visitor participation since its launch in 2000, making Excon-2015 the biggest-ever exhibition.

There were country pavilions from China, Finland, Germany, Italy, South Korea, Sweden, Turkey and  the UK, reiterating the potential of the Indian construction industry to grow t0 $5 marker share of $ ? 2.9 billion.

EVENT FACTSHEET

- Largest Construction Equipment Exhibition in South Asia

- 2,50,000 Sq.mts of exhibition display area

- UFI Approved Event

- 1000+ Exhibitors including 275 from Abroad

- 12 Country Pavilions China, Finland, Germany, Hongkong, Italy, South Korea, Sweden, Taiwan, Turkey, UK & USA

- 40,000+ Business Visitors

- 300+ Product Launches

- Industry Conferences by CII, BAI and ICEMA

- International Buying Delegates

- B2B Meetings Networking Forums